API Casing

Classification :

Oil country tubular goods

Key Words:

Oil country tubular goods

Description

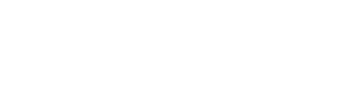

Casing is used for lining the complete borehole which has been dug into the ground to procure oil. Similar to the drill pipe, the oil well casing pipe is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. OCTG casing is large diameter pipe which are held in place in the borehole using cement.

The diameters of OCTG casing pipe range from 4.5″ to 36″. The well-cemented pipe acts as the structural component of the well and offer hole integrity. They prevent the well from collapsing when the drilling process is on. Good quality, well cemented casing can stay in place for the whole life of the well.

The oil well casing pipe are further divided into:

Conductor Casing – Conductor casing is the first boundary between the surface and the subsurface. It helps prevention of well collapse; it keeps away the groundwater and most importantly provides structural support. Conductor casing is installed in the ground by either drilling it or hammering it down. They are available in sizes ranging from 18″ to 36″.

Surface Casing – The purpose of Surface casing is primarily environmental and to ensure safety. It helps in separating the freshwater zones, offering protection from blowout and supporting the wellhead and blow out prevention equipment. Therefore surface casings are required to maintain very high safety standards. They are responsible for supporting the next casing in line. They may vary in size depending on their purpose, but the most common size of surface casing is 13 3/8”.

Intermediate Casing: Intermediate casing is not always required in all types of oil and gas production. If used, they are placed between the surface and the production casing. They are available in sizes ranging from 13 3/8” to 16”.

Production Casing – Production casing help provide structural integrity and pressure control of the hydrocarbon-bearing sections mainly during the production of oil.

Production Liner – Production liners can be suspended from the production casing or one of the previous casings. They help in reducing the cost significantly as the liner is not required to run through the full depth of the well. Liners can be pre-perforated to help save time and cost.

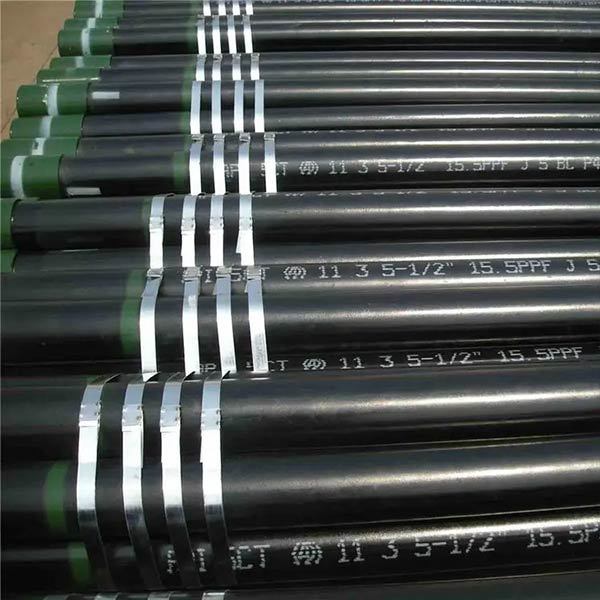

More casing pipes and their colors

Specification

API 5CT Well Casing Length:

API 5CT Casing | Range 1 | Range 2 | Range 3 |

4.88~7.62 | 7.62~10.36 | 10.36~14.63 |

Dimension

| Labels | OD(mm) | WT(mm) | J55/K55 | N80 | L80 | C90/T95 | P110 | Q125 | |

| 4 1/2 | 9.5 | 114.3 | 5.21 | PS | - | - | - | - | - |

| 10.5 | 114.3 | 5.69 | PSB | - | |||||

PACKING AND SHIPPING

We have established a professional international trade service team with a global sales network. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, Middle East and Africa

FACTORY APPEARANCE

The company has advanced production equipment and technical strength, adopts internationally advanced production technology and quality control system to ensure that each batch of steel can meet or exceed international standards. Equipped with a complete product production line, the main equipment includes cutting machines, bending machines, punching machines, water jet cutting machines, polishing machines, plate cutting machines, wire drawing machines, etc. Our products include carbon steel, stainless steel, steel pipes, steel coils, steel plates, building materials: bars, wires, spiral coils, round steel; pipes: seamless pipes, welded pipes; plates: cold and hot rolled plates/coils, thick plates, color coated plates (galvanized plates, color steel plates, galvanized aluminum steel), silicon steel, strip steel; steel sections: working channel steel, H steel, square steel, flat steel, ball flat steel; up to 72 kinds of steel, with a stock of more than 200,000 tons.

FACTORY APPEARANCE

Our products are complete in variety, sufficient in stock, of excellent quality, low in price and considerate in service. At the same time, we are also the designated supplier of many large enterprises, providing steel for major project renovations in many countries. At the same time, we have also established a professional international trade service team, with a global sales network. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and have established business in Peru, the Philippines, Russia, Ukraine, Belarus, Uzbekistan, Pakistan, Indonesia, Malaysia, South Africa and other places. Products are exported to more than 30 countries including Africa, Sri Lanka, Turkey, Vietnam, Laos, Brazil, Thailand, the Middle East, the United Arab Emirates, Morocco, Spain, the United States, New Zealand, Iran, etc.

RELATED PRODUCTS

GET A FREE QUOTE