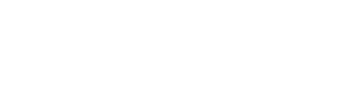

6061-T6 Aluminum foil

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

Classification :

Aluminum Foil

Key Words:

Aluminum Foil

About the aluminum

6061 aluminum alloy T6 hardness standard data and functions:

① The main alloying elements in 6061 alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect. Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

② The main alloying elements of 6061 aluminum alloy are magnesium and silicon, and Mg2Si phase is formed. If contain a certain amount of manganese and chromium, can neutralize the bad effect of iron; Sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; There is also a small amount of copper in the conductive material to offset the bad effects of titanium and iron on electrical conductivity; Zirconium or titanium can refine grain and control recrystallization structure. Lead and bismuth are added to improve machinability. Mg2Si is solidly dissolved in aluminum, which makes the alloy have the function of artificial age hardening. The main alloying elements in 6061 aluminum alloy are magnesium and silicon, with moderate strength, good corrosion resistance, weldability and good oxidation effect.

(3) Alcoa 6061-T651 is the main alloy of 6 series, which is a high quality aluminum alloy product after heat treatment and pre-drawing process; Alcoa 6061 has excellent machining performance, good corrosion resistance, high toughness and no deformation after processing, easy coloring film, excellent oxidation effect and other excellent characteristics

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Standard | ASTM GB JIS AISI,EN |

| Thickness | 0.006mm(6micron) - 0.2mm (200micron) |

| Width | 120- 1500 mm (tolerance:± 1.0mm) |

| Temper | O,F, H12, 114,H18,H22, H24,H26,H32, etc |

| Application | Aluminum foil is widely used in food, beverage, cigarette, medicine, photographic plate, household articles, etc. It is usually used as its packaging material, electrolytic capacitor materials, insulation materials for buildings, vehicles, ships and houses. |

| Price Term | Ex-work, FOB, CFR, CIF, etc |

| Delivery Time | 20-30 days. Standard size is in stock,prompt delivery or as order's quantity. |

| Package | Export standard package, Carton box or wooden case, or waterproof paper, or as customer's request. |

| The inner size of container is below: | |

| 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM | |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM |

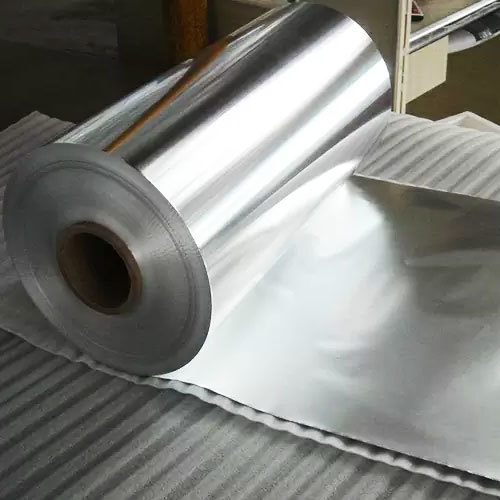

Aluminum Production Process

PACKING AND SHIPPING

We have established a professional international trade service team with a global sales network. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, Middle East and Africa

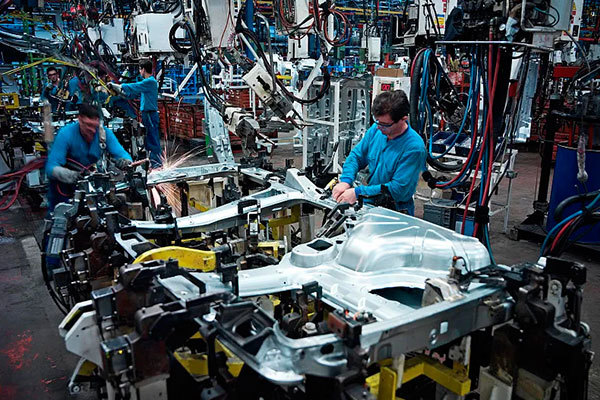

FACTORY APPEARANCE

The company has advanced production equipment and technical strength, adopts internationally advanced production technology and quality control system to ensure that each batch of steel can meet or exceed international standards. Equipped with a complete product production line, the main equipment includes cutting machines, bending machines, punching machines, water jet cutting machines, polishing machines, plate cutting machines, wire drawing machines, etc. Our products include carbon steel, stainless steel, steel pipes, steel coils, steel plates, building materials: bars, wires, spiral coils, round steel; pipes: seamless pipes, welded pipes; plates: cold and hot rolled plates/coils, thick plates, color coated plates (galvanized plates, color steel plates, galvanized aluminum steel), silicon steel, strip steel; steel sections: working channel steel, H steel, square steel, flat steel, ball flat steel; up to 72 kinds of steel, with a stock of more than 200,000 tons.

FACTORY APPEARANCE

Our products are complete in variety, sufficient in stock, of excellent quality, low in price and considerate in service. At the same time, we are also the designated supplier of many large enterprises, providing steel for major project renovations in many countries. At the same time, we have also established a professional international trade service team, with a global sales network. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and have established business in Peru, the Philippines, Russia, Ukraine, Belarus, Uzbekistan, Pakistan, Indonesia, Malaysia, South Africa and other places. Products are exported to more than 30 countries including Africa, Sri Lanka, Turkey, Vietnam, Laos, Brazil, Thailand, the Middle East, the United Arab Emirates, Morocco, Spain, the United States, New Zealand, Iran, etc.

RELATED PRODUCTS

GET A FREE QUOTE